How to make a continuity tester with light and sound

New product

Solve the faults in a simple way with this continuity tester with sound and light that you can do in a homemade way and with simple materials.

How to make a continuity tester with light and sound

Today I bring you at the request of a subscriber a fairly simple circuit to do with recycled materials and is quite useful as a search tool for those failures that are hidden behind a false contact, cut wire or fuse damaged. That's right, today I'm going to explain how to build a sound continuity tester.

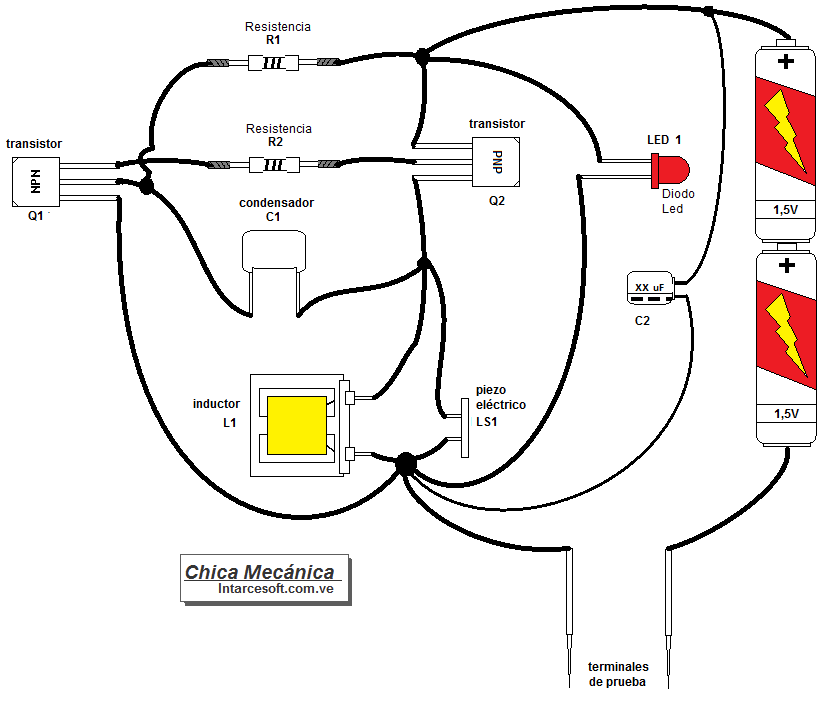

We need to build it:

- 01 NPN 2N2222 Transistor (Q1)

- 01 Transistor PNP 3906 (Q2)

- 01 Normal Red LED.

- 01 390 Ohms Resistor (R2)

- 01 47k ohms Resistor (R1)

- 02 1.5 V Batteries

- 01 Piezoelectric (LS1)

- 01 inducer or coil whose resistance is between [5 and 15] Ohms

- 01 Capacitor 33nF (C1)

- 01 Capacitor 100uF

Note: For the inductor or coil, take it out of a burnt saver bulb. It is the high frequency ballast works perfect on this device.

Mounting circuit

As you can see in the image above, the circuit has few elements, but has enough connections. Lol. This is why you have to be very careful when assembling do not be mistaken. Above all, in the bases of the transistors (the central leg of the transistor) because a bad connection at this point irreparably damages it.

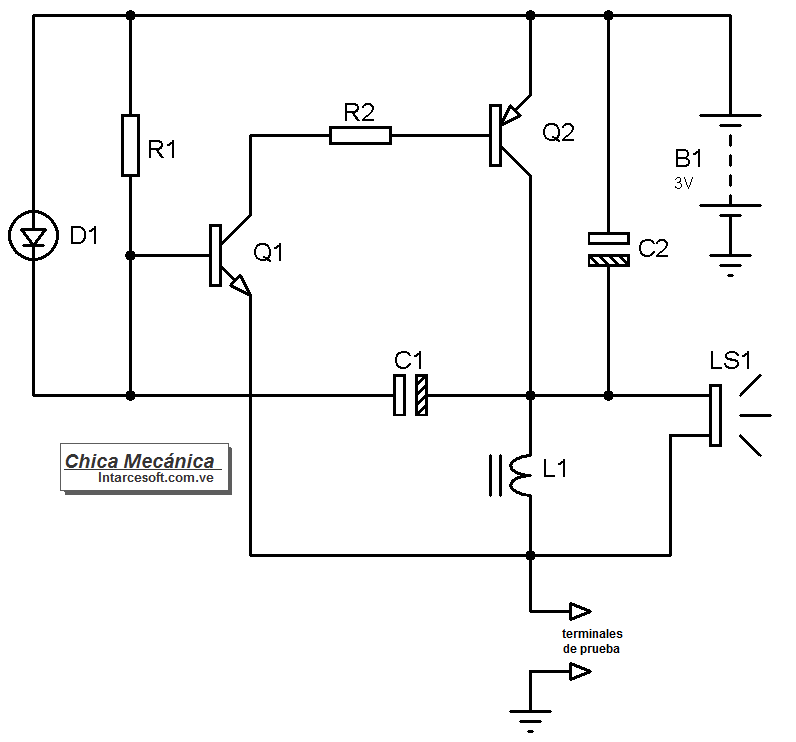

Anyway for the most experienced I leave this other circuit with electronic symbology to see better ; )

Publicidad.

How the Circuit works

Some of the issues I wanted to meet for this circuit were:

Make it as simple as possible "without using spider" (integrated circuits).

- That the current consumption was minimal.

- That out of sharp sound.

- Could somehow know whether or not there is continuity and its magnitude.

- Low operating voltage to be safe in TTL circuits.

This is a modified metronome whose association of Q1, Q2, R1 and C1 generate a very short-lasting pulse, where the frequency depends on the values of R1 and C1. Of course, to generate this pulse, it is necessary to connect a load to the output that is between 4 and 20 ohms preferably, in this case a small horn would look good. The problem is that they consume a lot of energy, so I decided to use a piezoelectric. To do this I added a small high impedance coil in parallel to achieve the oscillation that this element needs. And so left the circuit of the previous image that can be used with batteries of the type button to 3v obtaining a sound quite... say that audible (not to say annoying lol).

Its operation is simple, when placing a cable between the test terminals closes the circuit and initiates the process of oscillation at high frequency audible by the piezoelectric. The LED will light if low resistance is available between the terminals under test (between 0 and 150 ohms). Otherwise you will only hear a slight sound indicated by this to the operator that there is continuity of the circuit, but the impedance is high to circulate electric current.

How to use it?

When using the appliance, familiarise yourself with the sound at resistance 0 (join the two ends). In this way you can evaluate the amount of resistance that exists under test based on the sound.

Another important thing is to always check that there is no tension between the elements to be tested as the circuit will burn. As with other mid-level commercial testers. I did not include a surge protector in the design; ).

Connect the test leads to the element to be tested, pay attention to the sound and the ignition of the LED. The following table indicates the operation summary.

Publicidad.

Sound | Led On | Description of the problem |

Yes | Yes | Low or zero resistance, if both the sound and the lighting of the LED is strong. |

Yes | No | High resistance, between 150 and 1000 ohms. There is likely to be false contact or measuring an electrical circuit. |

No | No | No continuity |

Design Considerations

Make sure that the battery does not exceed 3, 5v or the LED will burn (note that it has no resistance).

If you do not have the piezo, remove the L1 coil and place C1 = 1uF and R1 = 10k ohms and a serial resistor to the LED of at least 690 ohms. Finally increase the operating voltage to 9v.

If you do not like the tone being generated and want to edit it, place R1 = 5000 ohms and add a 250 K ohms potentiometer in series. By changing its value, you can get different shades.

Well, that's all for today, I hope you like it and can implement it.

I leave a video of how I did it:

Do you have questions or doubts?

Questions or suggestions can use the form below and I will gladly answer them.

Publicidad.

Follow me on Social Networks

|  |

written by

Chica Mecánica

19/04/2018 https://www.instagram.com/mecanicachica/https://www.youtube.com/c/chicamecanica

Excelente nivel de detalle

Excelente Dennis. que pactico, muy bueno el nivel de detalles, motivas a querer aprender.

Chevere

Facíl como siempre Dennis.

Ask a question

NO registration required!

18 Question(s) answered

If the question you have has not yet been answered here, use the form below to ask something about this addon.

- Asked by jose jimenez

on 05/25/2018 Hola, podrias ayudarme, donde localizo los sensores de impacto frontales del chery orinoco 2015 sinc? cuantos son? donde estan ubicados en el carro? agradeceria de tu valiosa colaboracion Answer:

Caramaba Jose, ese es uno de los sensores que no he buscado. - Asked by Carlos Ruiz

on 07/17/2018 Estimada Ingeniera.Cuando dice del piezoelectrico ,se puede instalar uno de lo que tiene el circuito de Microonda.le agradezcosu opinion tecnica.Saludo cordial. Carlos Ruiz . Charallave Venezuela Answer:

Que tal Carlos, si te sirve chévere el de microondas. Lo único que espero, es que el electrodomestico este dañado, porque sino, no sabras cuando esté la comida caliente. jajajaja. - Asked by Emilio Gonzalez

on 09/04/2018 Dennis, No te gustan las arañitas o siempre quieres usar circuiteria sencilla, por que algunas veces se pueden hacer mas funciones con ellas y a veces con menos componentes. Answer:

Jajajaja. No me gustan mucho. Y es cierto que es posible hacer mejores componentes. - Asked by brian lewis zaranuatchs

on 10/18/2018 deseo saber como hacer un tester digital casero ya que se me quemo el mio y la verdad no tengo para c omprarme uno te lo agradezco ante mano Answer:

Caramba Brian, esta algo complicada tu pregunta. Es posible hacerlo mas sencillo de los analógicos. Con la agujita. - Asked by brian zaraniatchs

on 11/18/2018 hola, me puedes decir como hacer un tester analogico por favor me podrias mandar el diagrama con sus componentes, de verdad te lo agradezco Answer:

Caramba Brian, eso aparece en internet. Por los momentos no tengo el tiempo para realizar una busqueda y verificar si esta correcto. - Asked by Washington Miranda

on 05/24/2019 Este circuito es para carro Answer:

Si, para carro Washington. - Asked by Eduardo

on 07/07/2019 Fantastic Eduardo desde South Africa. Answer:

Excelent! Eduardo. - Asked by Gerardo

on 09/04/2019 hola r1 es de 47k o 10k porque en elvideo dice 10k pero en la lista de materiales dice 47k Answer:

Es de 47kOhms - Asked by juan

on 11/04/2019 buenas sra dennis, tengo una pregunta respecto a este circuito veo que trabaja en 3 voltios se puede hacer uno para trabajar en 12 voltios que materiales se requiere Answer:

Hay que hacer un rediseño Juan....cuando tenga un tiempito lo actualizo. - Asked by juan

on 11/04/2019 buenas sra dennis, este circuito es para 3 voltios hay forma de hacerlo para 12 voltios Answer:

Hay que hacer un rediseño Juan....cuando tenga un tiempito lo actualizo. - Asked by juan

on 11/05/2019 le pregunto porque estoy tratando de integrar varios equipos en uno solo para mejorar mi trabajo en mecanica y electroautome gustaria contactarla directamente Answer:

Por mi instagram @mecanicachica y proximamente por telegram @chicamecanica - Asked by César Espinoza

on 12/03/2019 Hola mi nombre es César, desde chile, muy buenos videos a subido, le felicito en primer lugar, fuerza y ánimo le mando. Bueno nose si ud tiene tiempo como para crear un buscador de cortocircuitos con bocina, osea q indique q el cable del ramal está cortado, está difícil este proyecto pero tengo fe en q ud lo podrá hacer, gracias Mi Whatsapp es +56968032115 o e-mail cesarespinozaaravena@gmail.com Estaré atento si me comenta de este proyecto, gracias Answer:

Que tal Cesar, gracias por tu sugerencia tu hablas de un probador de continuidad sonoro? o un buscador con punta que por fuera del cable indique donde esta cortado? - Asked by César

on 12/03/2019 Buenos días, consulta en esta pregunta don emilio está fecha le consulta por el sistema de trabajo y se refiere a las ARAÑITAS, a q se refiere, graciasPreguntada por: Emilio Gonzalez el 04/09/2018Dennis, No te gustan las arañitas o siempre quieres usar circuiteria sencilla, por que algunas veces se pueden hacer mas funciones con ellas y a veces con menos componentes.Respuesta: Jajajaja. No me gustan mucho. Y es cierto que es posible hacer mejores componentes. Answer:

Las arañitas son los circuitos integrados César, les digo asi porque parecen arañitas con el poco de paticas. jajajaja. - Asked by Douglas manzano

on 04/19/2021 Buenas tardes ingeniera mi pregunta es la siguiente el capasitor 33nf como se representa (104- 103- 102- 101 ) y así sucesivamente gracias felicidades mucho ánimo Answer:

Se representa 33 3 K. en Poliester. - Asked by Douglas manzano

on 04/19/2021 Disculpe la pregunté podría funcional con una batería de 3,7V gracias de nuevo ingr Answer:

Claro, sin problemas. - Asked by Nery

on 04/26/2021 Hi Dennise, un gusto saludarte desde los Angeles Ca. Bendiciones a tu canal en YouTube i sigue adelante???????????????? Answer:

GRacias Nery por tus palabras de apoyo. Un abrazote para ti. - Asked by Douglas Leal P

on 07/13/2021 Buenos días. En esta En esta dirección hay un video donde aparentemente se mide el campo electromagnético sin descubrir el cable a medir. Usted ha manejado este tipo de probador?. Sabe como funciona? https://www.youtube.com/watch?v=iuMDQLvht9kMuchas gracias por compartir sus conocimientos. Answer:

Hola Douglas, vi el video y ese probador puya el cable con una aguja. No es de campo ni nada de eso. Saludos para ti. - Asked by Nelson Antipaz

on 10/04/2021 Hola bendiciones para tu vida y familia Dennis es para saber si puedes ayudarme con un centauro 2008 1.6 motor Peugeot Ya que no me le llega la chispa a la bobina Ya se la cambié y me está activando los rele y bomba de gasolina pero no me llega los pulso a la bobina Answer:

Al parecer tienes o el fusible de bobina quemado, para eso hay que verificar si hay positivo en la bobina al pasar el suiche. Lo otro es que la salida de compu este dañada.